H2S Microsensor

You can choose the H2S microsensor with a tip size down to 10 µm for high spatial resolution of H2S microprofiles, and with a fast response time of down to <10 seconds, you get a reliable tool for studying H2S production and oxidation. Read more...

Two types of H2S microsensors

Unisense offers two types of H2S microsensors with different characteristics, SULF and H2S.

Both types are miniaturized amperometric sensors with a sensing anode polarized against an internal reference. Driven by the external partial pressure, H2S from the environment penetrates through the sensor tip membrane into the electrolyte where the H2S is ultimately oxidised by the anode. This generates a current in the pA range which is measured by a high quality picoammeter, such as the UniAmp Multi Channel.

Read more about the our two different types of H2S microsensors below.

Which H2S sensor should you choose?

Because of the higher signal-to-noise ratio and longer expected lifetime you should choose the type 1 sensor for most environment. However, if you are working with an application where hydrogen is present in significant concentrations, you should choose type 2.

To calculate total sulfide concentrations, you also need to measure the pH in the sample.

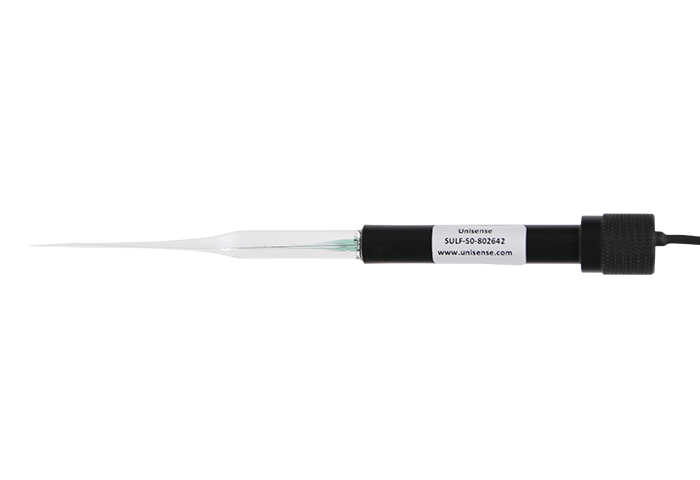

Type 1: SULF sensor

In the type 1 sensor (SULF), the signal is generated by oxidation of H2S directly on the anode in the tip of the sensor. The type 1 sensor is sensitive to hydrogen and should not be used in environments with high hydrogen concentrations. However, the type 1 sensor is not sensitive to light, and it has a higher signal-to-noise ratio. Additionally, you get a longer warranty and expected lifetime.

Type 2: H2S sensor

The type 2 (H2S) sensor is a customized sensor for environments containing H2. In the type 2 sensor (H2S-xxx), the H2S enters through the membrane in the tip and is converted to HS- ions in the alkaline electrolyte. This is immediately oxidized by ferricyanide, producing sulfur and ferrocyanide. The sensor signal is generated by re-oxidation of ferrocyanide at the anode in the tip of the sensor (see Jeroschewski et al. 1996). The internal guard electrode facilitates a constant ratio of ferri- to ferrocyanide in the electrolyte, thus minimizing the zero current. The ferri-/ferrocyanide complex is light sensitive and the sensors are coated black to minimize light interference.

Reference

| Feature | Standard | Options | Extra price for option selection |

|---|---|---|---|

|

Feature

Total length

|

Standard

150-200 mm

|

Options

70-350 mm

|

Extra price for option selection

20-50%

|

|

Feature

Diameter 20 mm from tip

|

Standard

< 2 mm

|

Options

< 1 mm

|

Extra price for option selection

10%

|

|

Feature

Diameter 50 mm from tip

|

Standard

8 mm

|

Options

< 2 mm

|

Extra price for option selection

20%

|

|

Feature

Glass shaft diameter

|

Standard

8 mm

|

||

|

Feature

Plastic shaft protection diameter*

|

Standard

11 mm

|

Options

Can be omitted

|

Extra price for option selection

|

*When mounted with in situ mini connectors, the shaft has no protection mounted, but fits directly into the in situ sensor mounts with pressure compensation. In situ sensors have a standard length of 130-160 mm.

| Item | Standard | Options | Extra price for option selection |

|---|---|---|---|

|

Item

Cable

|

Standard

Habia

|

||

|

Item

Cable length

|

Standard

1.5-2 m

|

Options

0-10 m

|

Extra price for option selection

Yes, depends on length

|

|

Item

Connector

|

Standard

LEMO

|

Options

BNC adaptor

|

Extra price for option selection

Yes, order separately

|

|

Item

In situ gold pin connector*

|

Standard

No

|

Options

Yes

|

*When mounted with in situ mini connectors, the shaft has no protection mounted, but fits directly into the in situ sensor mounts with pressure compensation. In situ sensors have a standard length of 130-160 mm.

| Attribute | Standard | Options | Extra price for option selection |

|---|---|---|---|

|

Attribute

Guaranteed lifetime

|

Standard

6 months

|

||

|

Attribute

Expected lifetime

|

Standard

> 1 Year

|

||

|

Attribute

Temperature range

|

Standard

-2-60°C, tip only

|

||

|

Attribute

Temperature coefficient

|

Standard

2-3% per °C

|

||

|

Attribute

Range

|

Standard

About 0-300 µM H2S in water

|

Options

0-10 mM

|

Extra price for option selection

20%

|

|

Attribute

Linear range

|

Standard

About 0-300 µM H2S in water | About 0-10 µM for LR (Low Range) sensors | About 0-1 µM for Ultra LR sensors

|

Options

0-10 mM

|

Extra price for option selection

20%

|

|

Attribute

Detection limit

|

Standard

0.3 µM

|

||

|

Attribute

Detection limit - Low Range sensors (only for tip sizes ≥ 50 µm)

|

Standard

10 nM

|

Options

|

Extra price for option selection

20%

|

|

Attribute

Detection limit - Ultra Low Range sensors (only for tip sizes 200 µm and 500 µm)

|

Standard

2-3 nM

|

Options

|

Extra price for option selection

20%

|

|

Attribute

Internal reference

|

Standard

Yes

|

||

|

Attribute

Waterproof

|

Standard

Yes

|

||

|

Attribute

Pressure tolerant sensing tip

|

Standard

Yes

|

||

|

Attribute

Spatial resolution

|

Standard

Equals outside tip diameter

|

||

|

Attribute

Signal drift

|

Standard

25% per month

|

| Item | Stirring sensitivity | Response time (90%) |

|---|---|---|

|

Item

SULF

|

Stirring sensitivity

<2%

|

Response time (90%)

<10 s | <20 s on Low Range sensors | <60 s on optional 2-3 nM sensors

|

| Feature | Standard | Options | Extra price for option selection |

|---|---|---|---|

|

Feature

Total length

|

Standard

150-200 mm

|

Options

70-350 mm

|

Extra price for option selection

20-50%

|

|

Feature

Diameter 20 mm from tip

|

Standard

< 2 mm

|

Options

< 1 mm

|

Extra price for option selection

10%

|

|

Feature

Diameter 50 mm from tip

|

Standard

8 mm

|

Options

< 2 mm

|

Extra price for option selection

20%

|

|

Feature

Glass shaft diameter

|

Standard

8 mm

|

||

|

Feature

Plastic shaft protection diameter*

|

Standard

11 mm

|

Options

Can be omitted

|

Extra price for option selection

|

*When mounted with in situ mini connectors, the shaft has no protection mounted, but fits directly into the in situ sensor mounts with pressure compensation. In situ sensors have a standard length of 130-160 mm.

| Item | Standard | Options | Extra price for option selection |

|---|---|---|---|

|

Item

Cable

|

Standard

Habia

|

||

|

Item

Cable length

|

Standard

1.5-2 m

|

Options

0-10 m

|

Extra price for option selection

Yes, depends on length

|

|

Item

Connector

|

Standard

LEMO

|

Options

BNC adaptor

|

Extra price for option selection

Yes, order separately

|

|

Item

In situ gold pin connector*

|

Standard

No

|

Options

Yes

|

*When mounted with in situ mini connectors, the shaft has no protection mounted, but fits directly into the in situ sensor mounts with pressure compensation. In situ sensors have a standard length of 130-160 mm.

| Attribute | Standard | Options | Extra price for option selection |

|---|---|---|---|

|

Attribute

Guaranteed lifetime

|

Standard

3 months

|

||

|

Attribute

Expected lifetime

|

Standard

> 6 months

|

||

|

Attribute

Temperature range

|

Standard

-2-60°C

|

||

|

Attribute

Range

|

Standard

About 0-1 mM H2S in water

|

Options

0-50 mM

|

Extra price for option selection

20%

|

|

Attribute

Linear range

|

Standard

About 0-300 µM H2S in water | About 0-100 µM for LR (Low Range) sensors

|

Options

0-20 mM

|

Extra price for option selection

20%

|

|

Attribute

Detection limit

|

Standard

0.3 µM | 30 nM for H2S-50LR | 20 nM for H2S-100/500/NP LR

|

||

|

Attribute

Internal reference

|

Standard

Yes

|

||

|

Attribute

Internal guard

|

Standard

Yes

|

||

|

Attribute

Waterproof

|

Standard

Yes

|

||

|

Attribute

Spatial resolution

|

Standard

Equals outside tip diameter

|

||

|

Attribute

Signal drift

|

Standard

50% per month

|

| Item | Stirring sensitivity | Response time (90%) |

|---|---|---|

|

Item

H2S

|

Stirring sensitivity

<2%

|

Response time (90%)

<10 s

|

|

Item

H2S-500 and FT-cell

|

Stirring sensitivity

<2%

|

Response time (90%)

<20 s

|

| Name | Formula | Interference for gases in gas phase (%) | Interference for gases dissolved in water (%) |

|---|---|---|---|

|

Name

Methane

|

Formula

CH4

|

Interference for gases in gas phase (%)

0*

|

Interference for gases dissolved in water (%)

0**

|

|

Name

Carbon dioxide

|

Formula

CO2

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Nitrogen

|

Formula

N2

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Oxygen

|

Formula

O2

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Air

|

Formula

O2, N2, Ar

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Nitrous oxide

|

Formula

N2O

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Ammonia

|

Formula

NH3

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Hydrogen

|

Formula

H2

|

Interference for gases in gas phase (%)

0.8

|

Interference for gases dissolved in water (%)

96

|

|

Name

Carbon monoxide

|

Formula

CO

|

Interference for gases in gas phase (%)

0.6

|

Interference for gases dissolved in water (%)

77

|

|

Name

Dimethyl sulfide

|

Formula

(CH3)2S

|

Interference for gases in gas phase (%)

18

|

Interference for gases dissolved in water (%)

18

|

|

Name

Methyl mercaptan

|

Formula

CH3SH

|

Interference for gases in gas phase (%)

174

|

Interference for gases dissolved in water (%)

44

|

|

Name

Ethyl mercaptan

|

Formula

C2H6S

|

Interference for gases in gas phase (%)

13

|

Interference for gases dissolved in water (%)

14

|

|

Name

Sulfur dioxide

|

Formula

SO2

|

Interference for gases in gas phase (%)

40

|

Interference for gases dissolved in water (%)

1

|

*Given as signal for the interfering species in % of H₂S signal at equal partial pressures

**Given as signal for the interfering species in % of H₂S signal at equal molar concentrations

| Name | Formula | Interference for gases in gas phase (%) | Interference for gases dissolved in water (%) |

|---|---|---|---|

|

Name

Methane

|

Formula

CH4

|

Interference for gases in gas phase (%)

0*

|

Interference for gases dissolved in water (%)

0**

|

|

Name

Carbon dioxide

|

Formula

CO2

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Nitrogen

|

Formula

N2

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Oxygen

|

Formula

O2

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Air

|

Formula

O2, N2, Ar

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Nitrous oxide

|

Formula

N2O

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Ammonia

|

Formula

NH3

|

Interference for gases in gas phase (%)

0

|

Interference for gases dissolved in water (%)

0

|

|

Name

Hydrogen

|

Formula

H2

|

Interference for gases in gas phase (%)

0.03

|

Interference for gases dissolved in water (%)

4

|

|

Name

Carbon monoxide

|

Formula

CO

|

Interference for gases in gas phase (%)

4

|

Interference for gases dissolved in water (%)

487

|

|

Name

Dimethyl sulfide

|

Formula

(CH3)2S

|

Interference for gases in gas phase (%)

3

|

Interference for gases dissolved in water (%)

3

|

|

Name

Methyl mercaptan

|

Formula

CH3SH

|

Interference for gases in gas phase (%)

117

|

Interference for gases dissolved in water (%)

30

|

|

Name

Ethyl mercaptan

|

Formula

C2H6S

|

Interference for gases in gas phase (%)

8

|

Interference for gases dissolved in water (%)

9

|

|

Name

Sulfur dioxide

|

Formula

SO2

|

Interference for gases in gas phase (%)

34

|

Interference for gases dissolved in water (%)

1

|

*Given as signal for the interfering species in % of H₂S signal at equal partial pressures

**Given as signal for the interfering species in % of H₂S signal at equal molar concentrations

| Type 1: SULF | Size and description | Options | Extra price for option selection |

|---|---|---|---|

|

Type 1: SULF

SULF-10

|

Size and description

8-12 µm - glass sensor

|

Options

3-5 µm

|

Extra price for option selection

20%

|

|

Type 1: SULF

SULF-25

|

Size and description

20-30 µm - glass sensor

|

||

|

Type 1: SULF

SULF-50

|

Size and description

40-60 µm - glass sensor

|

||

|

Type 1: SULF

SULF-100

|

Size and description

90-110 µm - glass sensor

|

||

|

Type 1: SULF

SULF-200

|

Size and description

175-225 µm - glass sensor

|

||

|

Type 1: SULF

SULF-500

|

Size and description

400-600 µm - glass sensor

|

||

|

Type 1: SULF

SULF-Eddy

|

Size and description

40-60 µm - for Eddy Correlation System

|

||

|

Type 1: SULF

SULF-50LR

|

Size and description

40-60 µm - low range

|

||

|

Type 1: SULF

SULF-100LR

|

Size and description

90-110 µm - low range

|

||

|

Type 1: SULF

SULF-500LR

|

Size and description

400-600 µm - low range

|

||

|

Type 1: SULF

SULF-MR

|

Size and description

400-600 µm - in guide

|

Options

100-400, 600-800 µm

|

Extra price for option selection

20%

|

|

Type 1: SULF

SULF-N

|

Size and description

1.1 x 40 mm - needle sensor

|

||

|

Type 1: SULF

SULF-NP

|

Size and description

1.6 x 40 mm - needle sensor for piercing

|

||

|

Type 1: SULF

SULF-NPLR

|

Size and description

1.6 x 40 mm - needle sensor for piercing - low range

|

||

|

Type 1: SULF

SULF-ST-1/4

|

Size and description

1/4'' steel tube

|

||

|

Type 1: SULF

SULF-SL-1/4

|

Size and description

FT-cell 1/4'' Swagelok Tee

|

||

|

Type 1: SULF

SULF-SL-1/8

|

Size and description

FT-cell 1/8'' Swagelok Tee

|

||

|

Type 1: SULF

SULF-PEEK-1/8

|

Size and description

FT-cell 1/8'' PEEK Tee

|

||

|

Type 1: SULF

SULF-PEEK-1/16

|

Size and description

FT-cell 1/16'' PEEK Tee

|

||

|

Type 1: SULF

SULF-FT-GLASS-6

|

Size and description

Glass FT-cell 6mm outer diameter

|

||

|

Type 1: SULF

SULF-FT-GLASS-8

|

Size and description

Glass FT-cell 8mm outer diameter

|

| Type 2: H2S | Size and description | Options | Extra price for option selection |

|---|---|---|---|

|

Type 2: H2S

H2S-10

|

Size and description

8-12 µm - glass sensor

|

Options

3-5 µm

|

Extra price for option selection

20%

|

|

Type 2: H2S

H2S-25

|

Size and description

20-30 µm - glass sensor

|

||

|

Type 2: H2S

H2S-50

|

Size and description

40-60 µm - glass sensor

|

||

|

Type 2: H2S

H2S-100

|

Size and description

90-110 µm - glass sensor

|

||

|

Type 2: H2S

H2S-200

|

Size and description

175-225 µm - glass sensor

|

||

|

Type 2: H2S

H2S-500

|

Size and description

400-600 µm - glass sensor

|

||

|

Type 2: H2S

H2S-Eddy

|

Size and description

40-60 µm - for Eddy Correlation System

|

||

|

Type 2: H2S

H2S-50LR

|

Size and description

40-60 µm - low range

|

||

|

Type 2: H2S

H2S-100LR

|

Size and description

90-110 µm - low range

|

||

|

Type 2: H2S

H2S-500LR

|

Size and description

400-600 µm - low range

|

||

|

Type 2: H2S

H2S-MR

|

Size and description

400-600 µm - in guide

|

Options

100-400, 600-800 µm

|

Extra price for option selection

20%

|

|

Type 2: H2S

H2S-N

|

Size and description

1.1 x 40 mm - needle sensor

|

||

|

Type 2: H2S

H2S-NP

|

Size and description

1.6 x 40 mm - needle sensor for piercing

|

||

|

Type 2: H2S

H2S-NPLR

|

Size and description

1.6 x 40 mm - needle sensor for piercing - low range

|

||

|

Type 2: H2S

H2S-ST-1/4

|

Size and description

1/4'' steel tube

|

||

|

Type 2: H2S

H2S-SL-1/4

|

Size and description

FT-cell 1/4'' Swagelok Tee

|

||

|

Type 2: H2S

H2S-SL-1/8

|

Size and description

FT-cell 1/8'' Swagelok Tee

|

||

|

Type 2: H2S

H2S-PEEK-1/8

|

Size and description

FT-cell 1/8'' PEEK Tee

|

||

|

Type 2: H2S

H2S-PEEK-1/16

|

Size and description

FT-cell 1/16'' PEEK Tee

|

||

|

Type 2: H2S

H2S-FT-GLASS-6

|

Size and description

Glass FT-cell 6mm outer diameter

|

||

|

Type 2: H2S

H2S-FT-GLASS-8

|

Size and description

Glass FT-cell 8mm outer diameter

|

Video Guides

We look into how SULF sensors are made, how they work, their specifications, and possible customizations.

Learn when to choose H2S over SULF, the applications as well as specifications and customizations.

Application Scientist Tage Dalsgaard shows you how to perform a 2-point calibration with H2S free water and one known H2S concentration

Quick Enquiry

Related products

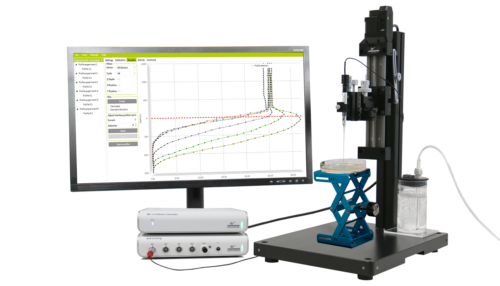

UniAmp Multi Channel for all Unisense sensors and electrodes including optical sensors

Microprofiles with extreme accuracy, high spatial and temporal resolution

Economic amplifier portfolio for single analytes - O2, pH/mV, H2, N2O or H2S

Miniaturized pH electrode

Sealed system to measure O2, H2, H2S, N2O, NO, pH, Redox, and temperature metabolism

Easy and cost-effective calibration of H2S and SULF microsensors

Applications

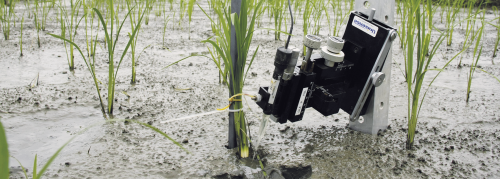

Learn in the laboratory - explore and confirm in the field!

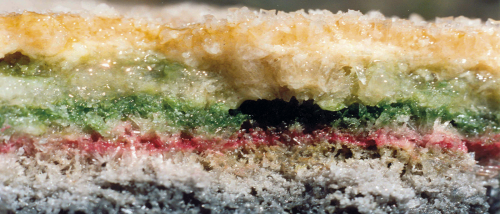

Needle sensors used for profiles in salt crusts.

Study plant root microenvironment

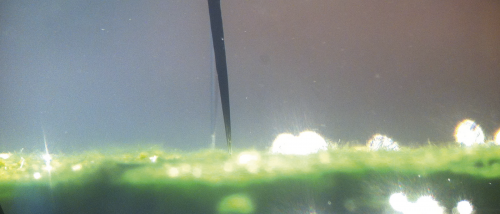

O2, H2S and pH microprofiles in biofilm